-

Продукти

- Лабораторни инструменти

- Лабораторни измервателни уреди и сонди

-

Онлайн анализатори

EZ Series Analysers

- Iron

- Aluminium

- Manganese

- Phosphate

- Chloride

- Cyanide

- Fluoride

- Sulphate

- Sulphide

- Arsenic

- Chromium

- Copper

- Nickel

- Zinc

- Ammonium

- Total Nitrogen

- Total Phosphorus

- Phenol

- Volatile Fatty Acids

- Alkalinity

- ATP

- Hardness

- Toxicity

- Sample Preconditioning

- Boron

- Colour

- Nitrate

- Nitrite

- Silica

- Hydrogen Peroxide

- EZ Series Reagents

-

Онлайн сензори и контролери

Датчици за pH и окислително-редукционен потенциал (ORP)

- 1200-S Redox

- 1200-S pH

- 12мм pH/Redox

- LCP pH/Redox

- Дигитален диференциален Redox

- Дигитален диференциален pH

- Диференциален pH

- Комбинация pH/Redox

- Химически вещества, реактиви и стандарти

- Автоматизирани лабораторни системи

- Тестови комплекти и ленти

-

Микробиология

Аксесоари и химикали Дехидратирана средаЛабораторни съдовеПодготвени среди

-

Лабораторно оборудване и запаси

Ръководства и справочни материали Стъклени съдове/Пластмасови съдове

- Claros Water Intelligence System

- Параметри

-

Софтуерни решения

-

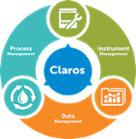

Интелигентната система за вода Claros

Основни елементи на продукта Process Management

- Решения за:

- Отстраняване на BOD/COD

- Нитрификация/денитрификация

- Отстраняване на фосфора

- Управление на утайките

Data Management- Решения за:

- Събиране

- Визуализация и анализи

- Отчитане

- Точност на данните

Instrument Management- Решения за:

- Техническо обслужване

- Отстраняване на неизправности

- Дистанционен достъп

- Сравнение на лабораторните и технологичните данни

Предизвикателства пред индустрията Съответствие с нормите Намаляване на разходите Дистанционни операции Управление на данните Оптимизация на процесите Техническо обслужване на оборудването

-

Интелигентната система за вода Claros

- Индустрии

- Сервиз

- Новини

Beverage Knowledge Center

With the industry leading products from our Orbisphere and Hach brands, you can now monitor and ensure the superior quality of your beverage. Provide consistent and reliable results in the lab, in-process and at-line that help you control quality, minimise costs and maximise uptime.

- Over 80 years of experience in the beverage industry and a global presence.

- With a product portfolio for influent, in-production and wastewater, we have the solutions for every application you need.

- Competent technical support team and service technicians are always available to support you and your products.

The new benchmark in oxygen monitoring: M1100 Luminescent Oxygen Sensor

In-line sensor for the determination of dissolved oxygen (DO) in beer and de-aerated water.

|

|

|

Final product quality control

ORBISPHERE 6110: Final package analysis for gas measurements. It has been designed to meet the practical needs of the at-line environment and to deliver a simple, high-quality user interface. |

Das Gerät wurde speziell für die praktischen Anforderungen im Abfüllbetrieb entwickelt und verfügt über eine übersichtliche, hochwertige Benutzeroberfläche.

|

Quality and efficiency

DR 6000 UV-VIS Spectrophotometer: The UV-VIS spectrophotometer delivers top performance for both routine laboratory tasks and demanding photometry applications.

DR 6000 UV-VIS Spectrophotometer: The UV-VIS spectrophotometer delivers top performance for both routine laboratory tasks and demanding photometry applications.

|

|

New methods in photometry: Ensuring accuracy in the analysis of bitterness and colour

Photometry is an important part of modern laboratory activity within a be brewery. The determination of bitterness units, colour and photometric iodine samples are just some examples of the routine analysis that takes place in a brewery laboratory. These methods involve various enzymatic detections, such as the determination of alcohol or sugars (sucrose, fructose and glucose). Read the whole story and find out more...

Photometry is an important part of modern laboratory activity within a be brewery. The determination of bitterness units, colour and photometric iodine samples are just some examples of the routine analysis that takes place in a brewery laboratory. These methods involve various enzymatic detections, such as the determination of alcohol or sugars (sucrose, fructose and glucose). Read the whole story and find out more...